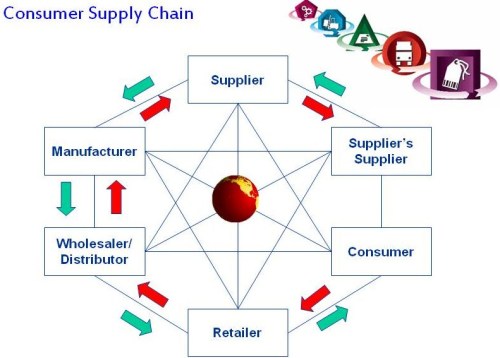

As we all know that Logistics is part of supply chain management process. Where as the Logistics deals with forward movement of goods within any supply chain, reverse logistics manages the reverse movement of goods, in other words returns management within supply chain function. Reverse flow is as important as forward movement in any supply chain. By examining a consumer supply chain process flows, one can conclude that reverse flows are very critical and important function within supply chain to recover the product cost comprehensively and at the same time helps in safe disposal of waste.

Source: Krumwiede & Sheu

According to CLM definition, managing reverse flows is part of Logistics Management.

“Logistics Management is that part of Supply Chain Management that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption in order to meet customers’ requirements”

This means, Logistics is part of supply Chain function and reverse logistics is part of Logistics function and both Logistics and Reverse Logistics are part of Supply Chain function. Reverse logistics also deals with moving the product from point to point. However the difference is that it moves from point of consumption to point of origin. Now let us review the scope of reverse logistics by examining the definition of reverse logistics.

“The process of planning, implementing, and controlling the efficient, cost effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal.” Reverse Logistics Executive Council.

What is evident from the above definition is that, reverse logistics helps business in product recycling in order to recapture the value and its disposal. All returns need not be financial write offs, some could be refurbished and sold again and in some cases part of the product could be recycled/remanufactured. Apart from recycling the product, reverse logistics plays a critical role for some organizations in asset (e-waste/chemicals) disposition to protect environment and also recover the data from the IT hardware in order to avoid data thefts.

Reverse Logistics Functions:

By examining the definition one can understand that the objectives of reverse logistics are to maximize the value recovery and safe disposal of waste.

Maximization of Value recovery:

If product intended for a sale is returned by the customer, the product cost is not recovered. One of the basic objectives of supply chain is to maximize the product margins. In order to achieve this objective, organizations through reverse logistics functions under take the following activities to maximize the revenue recovery.

- Return to suppliers;

- Resell;

- Refurbish/Recondition;

- Remanufacture;

- Reclaim parts;

- Recycle;

What are the reasons that would result in above mentioned activities?

- Defects: Products are generally returned if the product doesn’t meet the quality standards set by the manufacturers. In a high cost product segment, the defects are rectified and where as in low cost products segment, replacement will be offered and defective product is returned to reverse logistics hub for refurbishing or remanufacturing.

- Product Recalls: Manufacturers may recall the product from time to time to address the product quality issues which cannot be rectified in the field.

- Competitive Reasons: In order to thrive in the retail market all major players agree to take back product if the prescribed conditions are followed in order to gain confidence of the consumer.

- Abuse: Some consumers to make use of the returns policy and abuse the system in order to achieve individual gains thus triggering reverse flows.

- Charity: Some organizations use reverse logistics function in order to achieve their philanthropic objectives. Goodwill gained through this process helps in maximizing revenue recovery. This practice is prevalent in food industry; star hotels distribute the leftovers to the needy on a daily basis.

- Maximization of product margins: We often hear about trade-in offers in almost all industries. Organizations explore the possibility to recycle the parts cannibalized from the trade-in products in order maximize the product margins.

- NPI: New product introduction generally triggers the reverse flows in order to clear the channel inventory. A new product always triggers curiosity among the buyers which could boos the top line revenue.

Safe Disposal:

Materials that contain hazardous elements should be properly disposed to protect the environment from hazardous chemicals and compounds. Materials such as lead, mercury, lithium, and other forms of toxic waste are considered hazardous and subject to strict governmental environmental compliance regulations.

Agencies such as U.S. Environmental Protection Agency (EPA) and state environmental agencies regulate the impact of businesses on the environment. These agencies develop and enforce regulations that implement environmental laws enacted by the government. The second objective of reverse logistics function is safe disposal of waste. Safe disposal has become mandatory due to above mentioned government legislations aimed at protecting the environment.

Industry Scope:

Reverse Logistics function is critical to all industries but very important to the following industries:

- Publishing – Reverse flow was introduced several decades ago. In order to encourage sellers to stock new books, publishers began the reverse flow of unsold books. The returned books were used in recycling in order to maximize the product margins. “Each return costs the publisher 25 cents in transportation, and many books are destroyed that typically cost between $2 to $2.50 to print.” Dr. Dale S. Rogers and Dr. Ronald S. Tibben-Lembke.

- IT Hardware and Electronics – This industry is typically defined as, “an industry with 60-day product life cycles and 90-day warranties. Of course customers are going to bring products back.” Same as publishing industry, in order to encourage customers to buy new products, companies introduced a marketing technique called trade-in and that encouraged customers to get rid off the old product and own new product and at the same time recover some cost out of old product. Further, due to short product life, obsolescence causes return flows. According to a study completed by Carnegie Mellon University, approximately 325 million personal computers will have become obsolete in the United States in the 20-year period between 1985 and 2005. Out of that number, it is estimated that 55 million will be placed in landfills (safe disposal) and 143 million will be recycled. As margins are very low in IT hardware industry, organizations maximize revenue recovery in order to improve product margins. It is also common practice to eliminate competitor products from the market place; companies take back competitors products as trade-in and recycle the components.

- Chemicals and Paints – “Paint is a mixture of four basic ingredients: Pigments, Resins, Solvents and Additives.” It’s the solvent used in the paint that determines how it may disposed.

- Retail – “Satisfaction guaranteed” sometimes means returns. Retailers under immense competition offer returns as a competitive strategy to attract customers. However, some abuse returns policy. According to UK’s Cranfield School of Management 30% of returns are seen in catalog retailing amounting to 2.8 million worth of goods. According to John Shore, 90% of the retailers ignore returns processing and do not have any system in place to manage the returns. The returned products often end up in a corner of warehouse, loosing focus and value ultimately.

- Consumer Electronics – In 1998 Consumer Electronics returns were estimated at $13.8 Billions in US alone according to Techpulse360. According to Sprague returns can account for 2 to 3 percent of a retailer’s sales and 5 to 6 percent of a manufacturer’s sales in consumer electronics. According to one report annual return rate was as high as 27% in consumer electronics industry in US.

- Automotive – It is a common practice that automobiles at its end of life will end up with salvage yard and some of the parts are recycled. According to Willam P. Steinkuller, automotive recyclers handle more than 10 million vehicles every year. Their efforts supply more than 37 percent of the United States ferrous scrap for the scrap-processing industry. It is a common practice in auto industry to remanufacture products. It is estimated that the worth of remanufactured automotive parts is more than 34 Billions (APRA).

- Food – Major star hotels engage in charity in distributing the leftovers to the needy. This activity may not result in any commercial gains, but will end up with improved goodwill which may help improve organizations top line revenues. Currently, a local company in Singapore recycles soya bean waste, spent grains and spent yeast into animal feed. A local food waste treatment plant was also set up last year to turn food waste from food courts, hotels and factories into compost and biogas.

Barriers to Reverse Logistics:

Reverse logistics may not be considered as a priority in many organizations. I was involved in a research supervision in New Zealand and results validated my belief that organizations do not allocate resourced required to manage reverse flows efficiently. Around 24% respondents believe that lack of proper reverse logistics IT systems is the biggest barrier and equal number of respondents felt that lack of importance is also a factor. Apart from above, lack of financial and human resources (36%), management inattention (12%) and legal issues (4%) were identified as barriers. These findings were some what closely matched with the survey conducted by Dr. Dale S. Rogers and Dr. Ronald S. Tibben-Lembke.

Managing reverse flows effectively in any organization is relevant and critical. The reusability of the product would determine the complexity and importance of reverse logistics within an organization. Many retail companies have recognized the importance and established hubs to handle reverse flows. Where as IT industry recognized it long back and outsourced this function for both recycling and safe disposal. The survey conducted in NZ revealed that majority do not outsource the reverse logistics function and at the same time they do not focus on this activity. The best method to handle non-core functions is to outsource the same. Instead of managing operations, manage KPIs to deliver the targeted results. With growing awareness of environmental protection, safe disposal methods will also improve in developed economies and in the process third world countries should not become dumping grounds for hazardous waste.